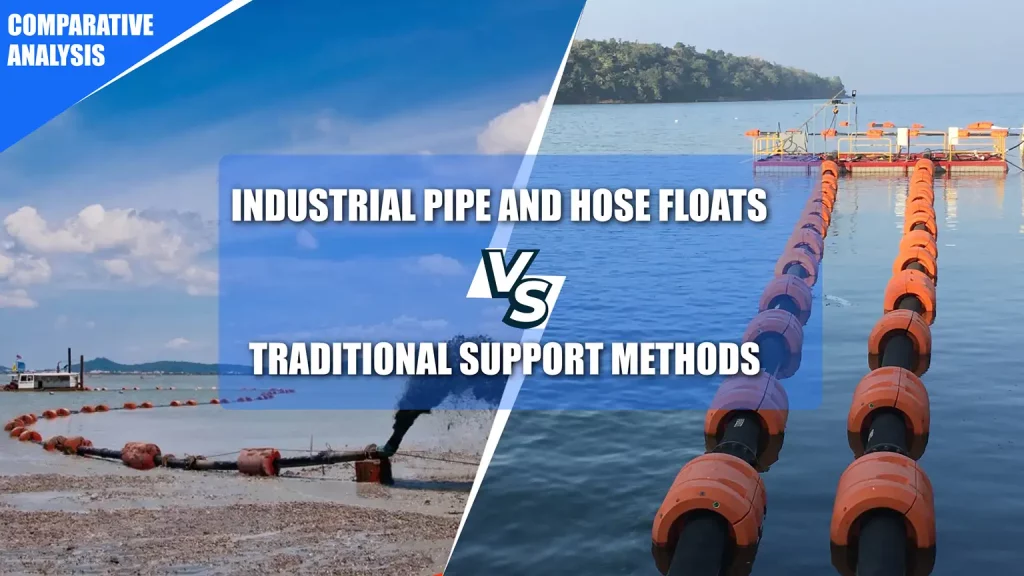

Support systems are vital for the stability and efficiency of industrial pipes and hoses, crucial in various industries such as oil and gas, mining, and wastewater treatment. This blog delves into two main categories of support methods: innovative industrial pipe floats and the more traditional support methods. By comparing and contrasting these approaches, we aim to provide insights that will help readers make informed decisions based on the specific needs of their applications.

Industrial Pipe and Hose Floats: Detailed Overview

Definition and Function

Industrial pipe and hose floats are specialized support accessories designed primarily to keep pipelines and hoses afloat, providing optimal positioning and protection within various aquatic environments. These devices typically encapsulate the pipe or hose, offering buoyant support that ensures stable and secure operations. By maintaining the conduit at a required elevation above the seabed or riverbed, floats prevent physical wear and tear while facilitating maintenance and inspection tasks.

Types and Varieties

The market offers a diverse range of industrial pipe and hose floats tailored to meet the specific demands of different applications:

- Foam-filled Floats: These are commonly used due to their robustness and reliability. The foam core provides consistent buoyancy even if the outer shell is compromised.

- Inflatable Floats: These floats offer adjustable buoyancy and are ideal for applications where water levels vary significantly. They can be inflated or deflated according to the specific operational needs.

- Solid Plastic Floats: Made from durable plastics like polyethylene, these floats are lightweight, resistant to impact, and immune to corrosion, making them suitable for various water conditions.

Each float type is designed to offer unique benefits and is suitable for specific operational conditions, from calm waters to areas with high mechanical stresses, such as near water intakes or in fast-flowing rivers.

Advantages

The use of pipe and hose floats brings several critical benefits to industrial operations:

- Buoyancy: The primary advantage is their ability to ensure that pipes and hoses maintain flotation. This is crucial in marine and freshwater environments where exposure to abrasive substances on the seabed can cause significant damage.

- Flexibility: Floats can accommodate changing water levels and dynamic environmental conditions without compromising the pipeline’s structural integrity. This is particularly important in areas subject to tidal changes or seasonal variations in water flow.

- Ease of Installation: Many float designs prioritize ease of deployment, featuring quick-release mechanisms and modular designs that significantly reduce setup times and allow for rapid reconfiguration.

- Adaptability: They are versatile enough to be used in various environments, from relatively static water bodies to flowing waters, providing reliable support under varying hydrological conditions.

Limitations

Despite the numerous advantages, there are several drawbacks to consider when opting for pipe and hose floats:

- Cost: The initial cost of high-quality floats can be significant compared to traditional support methods like fixed supports or makeshift solutions.

- Maintenance: TRegular inspections and maintenance are necessary to ensure ongoing performance and durability, especially for floats used in dynamic or environmentally harsh conditions. This might involve checking for and repairing wear and tear, leaks, or UV damage.

- Susceptibility to Damage: Depending on the material and construction, some floats can be vulnerable to UV degradation, punctures from sharp objects, or abrasion from sandy or rocky underwater environments. It is crucial to mitigate these risks by selecting the correct float type for the specific conditions it will face.

Traditional Support Methods: In-Depth Overview

Overview

Traditional support methods for industrial pipes and hoses rely on fixed structures to provide physical support. These methods typically involve using concrete blocks, wooden buoys, and metal stands that either support the infrastructure from underneath or securely anchor it in place. Designed primarily for stationary applications, these supports are commonly seen in environments where the position and elevation of the pipeline or hose can be adjusted infrequently.

Advantages

The use of traditional support methods comes with several key benefits that make them a viable option for many industrial scenarios:

- Stability: One of the primary advantages of traditional supports is the stable and robust physical support they provide. Structures like concrete blocks and metal stands are particularly effective in stationary applications where minimal movement of the pipeline or hose is expected. This stability is crucial for applications involving high-pressure flows or heavy materials.

- Durability: Materials used in traditional supports, such as concrete and metal, are selected for their strength and endurance. These materials can withstand harsh environmental conditions, including extreme temperatures, corrosive substances, and physical wear, making them suitable for long-term use.

- Lower Upfront Costs: Traditional support methods generally involve materials and techniques that are less specialized than those used in floating systems. This often translates into lower initial costs, making these methods attractive for projects with limited budgets or for applications where the cost-benefit analysis favors a less expensive, albeit less flexible, solution.

Limitations

Despite their advantages, traditional support methods also come with significant limitations that must be considered:

- Limited Adaptability: Traditional supports must be better suited for environments where water levels fluctuate significantly or where mobility of the pipeline or hose might be required. Their fixed nature means that any change in environmental conditions can necessitate a complete reconfiguration of the support system, which can be impractical and costly.

- Environmental Impact: Installing fixed supports, especially those involving large concrete blocks or extensive ground disturbance, can notably impact local ecosystems. In aquatic settings, for example, placing concrete supports on the riverbed or seabed can disrupt habitats and affect local flora and fauna. Additionally, the construction and maintenance work associated with these supports often increases sedimentation and pollution.

- Installation and Maintenance Complexity: Traditional support structures typically require heavy machinery and significant labor input to set up, which can increase the complexity and cost of installation. Furthermore, once installed, these supports are often difficult to adjust or move, making maintenance and any necessary modifications challenging and potentially expensive.

Comparative Analysis

Cost-effectiveness

While traditional methods may have lower initial costs, the long-term value and operational savings floats provided through reduced maintenance and operational flexibility can justify the higher initial investment.

Installation and Maintenance

Floats are generally more straightforward and quicker to install than traditional methods, often requiring more extensive setup and ongoing maintenance. Floats also offer more straightforward adjustment and relocation if necessary.

Adaptability and Versatility

Floats excel in adaptability, performing well under various environmental conditions and water levels, unlike fixed supports that are less flexible.

Environmental Impact

Pipe and hose floats tend to have a lesser environmental impact during installation and use compared to traditional methods, which can disrupt local ecosystems and require more invasive installation procedures.

Conclusion

Choosing between industrial pipe and hose floats, and traditional support methods involves carefully considering various factors, including cost, performance, adaptability, and environmental impact. This comparative analysis highlights the importance of assessing your application’s specific needs and conditions to determine the most suitable support method. We encourage readers to thoroughly evaluate their requirements and the advantages and disadvantages of each option before making a decision, ensuring the chosen method aligns with operational needs and environmental responsibilities.