Introduction

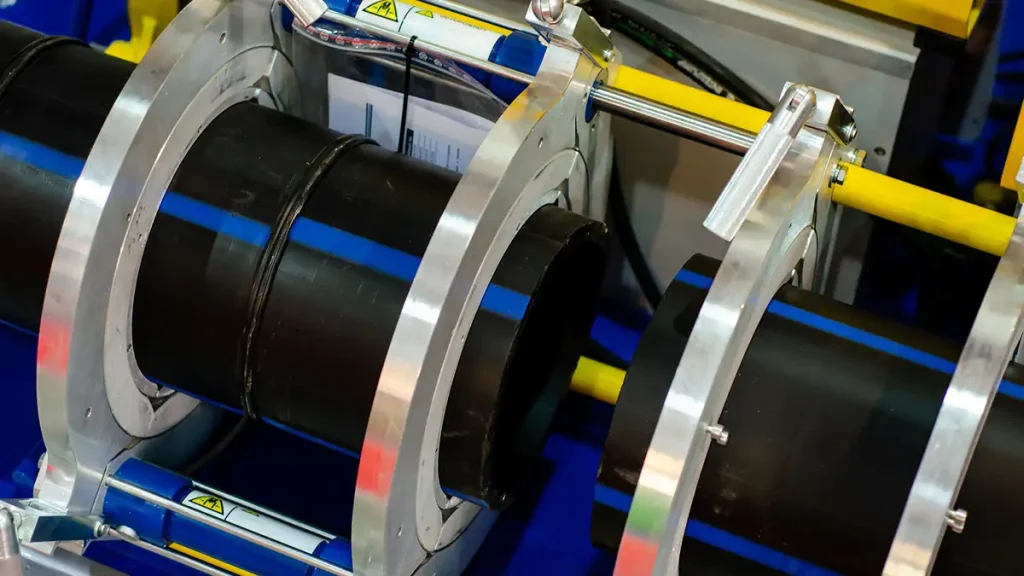

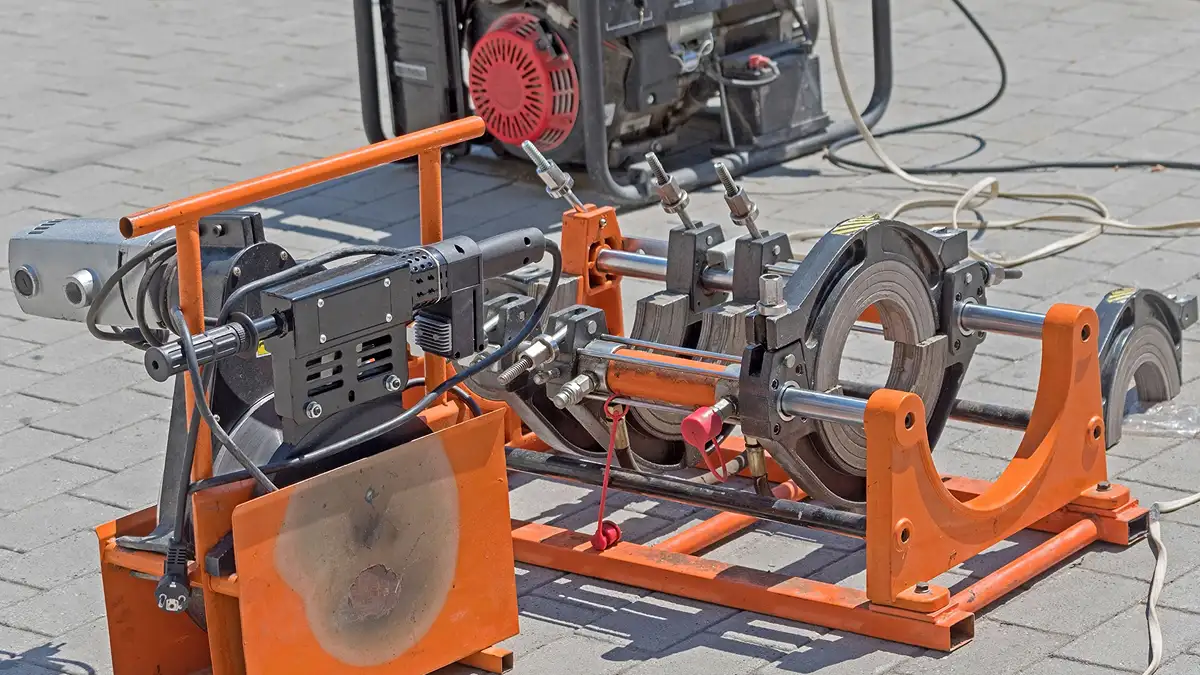

HDPE (High-Density Polyethylene) pipe fusion has become a critical joining method in industries where pipeline integrity, durability, and cost efficiency are paramount. From long-distance water supply networks in municipal infrastructure to slurry and chemical transport systems in mining, oil, and gas operations, the ability to create strong, leak-free joints is central to project success. At the core of this process is the HDPE fusion machine—specialized HDPE fusion equipment designed to heat and fuse pipe ends into a single continuous piece without the need for mechanical fittings.

For procurement heads, engineering managers, project contractors, and decision-makers in government and heavy industry, understanding the operational and safety aspects of HDPE pipe fusion is more than a technical detail—it’s an investment in performance, compliance, and return on capital. These machines operate under high temperatures and pressures, meaning that a disciplined approach to safety not only protects personnel but also ensures consistent weld quality and avoids costly downtime.

This blog focuses on the most important safety protocols for operating an HDPE fusion machine effectively. It brings together industry best practices, manufacturer recommendations, and field-proven measures to help teams maintain safety, protect assets, and maximize the operational lifespan of their HDPE fusion equipment.

Hazards of Operating an HDPE Fusion Machine

Operating an HDPE fusion machine involves several inherent hazards that can lead to serious injuries if proper safety protocols are not followed. Understanding these risks is crucial to ensuring both operator safety and the integrity of the HDPE fusion process. Below are some of the most common hazards associated with using HDPE fusion equipment in industrial settings:

Impact and Crush Injuries

HDPE fusion machine generates high pressure during operation, and any contact between the operator’s body and the machine’s moving parts, such as the heating plate or pipe sections, can result in severe impact or crush injuries. In addition, manually lifting and repositioning heavy HDPE pipes can cause accidental crushing, leading to potential harm.

Burns from High Temperature

One of the most significant hazards when working with HDPE pipe fusion is the risk of burns. The fusion process involves heating the pipe ends and the machine’s heating element to temperatures above 200°C, which can cause severe skin burns if there is accidental contact. Operators must be cautious around hot surfaces and always wear the appropriate PPE, including gloves and face shields.

Electric Shock

Improper electrical connections, worn cables, or operating in damp conditions significantly increase the risk of electric shock when using HDPE fusion equipment. Electrical safety measures, such as regular equipment inspections and ensuring proper grounding, are essential to preventing electrical accidents in the workplace.

Essential Safety Precautions for HDPE Fusion Machine Operation

Operating an HDPE fusion machine safely requires strict adherence to established safety protocols. The right precautions not only safeguard operators but also ensure that the HDPE pipe fusion process is completed without interruptions, maximizing productivity and minimizing risks. Below are key safety measures to follow when using HDPE fusion equipment:

Personal Protective Equipment (PPE)

When operating an HDPE fusion machine, wearing the appropriate PPE is essential to protect workers from burns, impact injuries, and electrical hazards. Operators should wear:

- Safety glasses or face shields to protect the eyes from flying debris and heat.

- Heat-resistant gloves to avoid burns from hot surfaces.

- Steel-toed boots for foot protection against falling or crushing injuries.

- In environments where fumes are a concern, respirators should be used to prevent inhalation of potentially hazardous fumes released during HDPE pipe fusion.

Machine Inspection and Maintenance

Before starting any work with HDPE fusion equipment, it is vital to inspect the machine and all related components. This includes:

- Checking the fusion machine’s power connections to ensure they are intact and properly grounded.

- Verifying that the heating plates and clamps are working correctly.

- Ensuring that calibrated temperature controls are functioning accurately to prevent overheating, which could cause pipe damage or defective welds. Regular maintenance and servicing of the HDPE fusion machine helps avoid unexpected malfunctions during operation, reducing downtime and the risk of accidents.

Adherence to Manufacturer Guidelines

Each HDPE fusion machine comes with a specific set of operational guidelines provided by the manufacturer. It’s crucial to follow these instructions to ensure the machine is used properly and safely. This includes:

- Setting the correct fusion temperature (typically between 200–240°C for most HDPE pipes).

- Understanding pressure settings and ensuring the equipment is calibrated correctly.

- Following recommended welding times to guarantee a consistent, leak-proof weld.

Adhering to these guidelines minimizes the risk of improper welds, equipment failure, and safety hazards.

Workplace Safety

Creating a safe environment for HDPE pipe fusion operations is just as important as machine safety. Ensure that the workspace is:

- Clean and free from clutter or obstructions that could impede the fusion process or lead to accidents.

- Well-ventilated to avoid the buildup of fumes released during the fusion of HDPE materials.

- Free from flammable materials such as oils, solvents, or papers that could catch fire from the fusion process or sparks.

In addition, make sure a fire extinguisher is within reach at all times, particularly in confined or high-risk areas where welding or heating elements are in use.

Trained Operators

Only qualified operators should be allowed to operate the HDPE fusion machine. Training ensures that operators:

- Understand how to safely operate HDPE fusion equipment and be familiar with its controls.

- Are knowledgeable about the safety features and emergency shutdown procedures.

Handling Hot Equipment Safely

An important safety precaution when operating HDPE fusion equipment is avoiding direct contact with hot surfaces. The HDPE fusion machine’s heating plates can reach temperatures that are capable of causing serious burns. Operators should:

- Use tools such as brushes or sticks to move or adjust hot components.

- Ensure all workers are aware of the hot zones around the machine to avoid accidental contact.

- Never attempt to touch any heated parts without protective gloves.

Safe Pipe Handling

HDPE pipes, while durable, can be heavy and cumbersome to handle. When working with long or large diameter pipes, it’s crucial to:

- Use mechanical aids like cranes or forklifts to move large pipes instead of relying on manual lifting, which can lead to strain injuries.

- Ensure proper pipe support when cutting, fitting, or welding to prevent damage or injury from sudden pipe movements.

- When moving smaller pipes, follow ergonomic lifting techniques to prevent musculoskeletal injuries.

Trench and Confined Space Safety

In many cases, HDPE pipe fusion occurs in trenches or confined spaces. These environments introduce unique safety concerns, such as:

- Collapse risks from trench walls.

- Poor ventilation could lead to the buildup of hazardous fumes or a lack of oxygen.

To mitigate these risks, operators should: - Use shoring or protective barriers to prevent trench collapse.

- Ensure proper ventilation and airflow in confined spaces.

- Always follow confined space entry protocols to ensure the safety of personnel working in these challenging environments.

Fusion Temperature: Achieving Optimal Weld Strength

Achieving a strong, reliable weld in HDPE pipe fusion depends on maintaining the correct fusion temperature. Whether using an HDPE fusion machine for large-scale municipal infrastructure projects or more specialized applications in the mining and oil and gas industries, the right temperature is essential to ensure a durable, leak-proof connection. Improper temperature settings can lead to weak joints that are prone to failure, resulting in costly repairs and operational downtime.

The Importance of Proper Fusion Temperature

The correct fusion temperature is crucial in determining the strength and longevity of the welded joint. For most HDPE pipes, the optimal fusion temperature range typically falls between 200°C and 240°C (392°F and 464°F). Within this range, the material reaches the ideal viscosity, allowing the fusion machine to create a seamless bond between pipe ends.

Operating an HDPE fusion machine outside this temperature range can result in various issues:

- Overheating can cause the HDPE material to degrade, weakening the weld and potentially introducing cracks or leaks.

- Underheating can prevent the pipe ends from properly fusing, leading to an inadequate joint that will not withstand pressure or environmental stress.

Adjusting for Special Conditions

In some cases, external factors such as ambient temperature or the size of the pipes may require slight adjustments to the fusion temperature. For instance:

- Cold weather may necessitate a higher fusion temperature to ensure proper pipe fusion, as the cooler temperatures can cause the material to harden more quickly.

- Larger diameter pipes may require longer heating times and potentially a slightly higher temperature to ensure that the entire pipe circumference is adequately fused.

For these situations, always refer to the manufacturer’s specifications for the HDPE fusion machine and make adjustments as necessary. This ensures that the welding process remains consistent and results in high-quality, long-lasting joints.

Ensuring Temperature Accuracy

One of the most effective ways to maintain the correct fusion temperature is to use an HDPE fusion machine with digital temperature controls. These machines allow for precise monitoring and adjustment of the fusion temperature, ensuring the process stays within the recommended range. The digital controls also reduce human error, providing an added layer of consistency to the fusion process.

It is also important to regularly calibrate the HDPE fusion machine to ensure that the temperature readings remain accurate. Over time, fusion equipment can experience wear and tear, which may affect temperature regulation. A calibrated machine ensures that temperature discrepancies are caught early, preventing poor-quality welds.

Fusion Time and Temperature Coordination

The proper fusion temperature is only one part of the equation. Equally important is the amount of time the HDPE fusion machine applies heat to the pipe ends. The heating time must be carefully coordinated with the temperature to achieve the best fusion results. If the pipe is heated for too long, it may cause degradation of the material. Conversely, insufficient heating time may result in a weak weld.

Operators must ensure that the fusion time is calibrated to the temperature settings and the specific type of HDPE pipe being used. This is particularly critical in high-stakes projects like pipeline construction for the oil and gas industry, where weld integrity is non-negotiable.

Key Takeaways

When operating an HDPE fusion machine, prioritizing safety and following proper procedures is essential for both operator’s well-being and the quality of the fusion process. Ensuring a safe work environment not only reduces the risk of accidents but also enhances the operational efficiency of the HDPE pipe fusion process, leading to reliable and durable pipeline systems. Below are the key takeaways for anyone involved in the operation of HDPE fusion equipment:

1. Prioritize Safety Protocols

The importance of adhering to safety protocols cannot be overstated. Operators must be trained in how to handle an HDPE fusion machine safely, wear the appropriate PPE, and follow manufacturer guidelines. By doing so, workers can avoid risks like burns, crush injuries, electrical shocks, and inhalation of fumes. Regular safety checks and equipment maintenance further ensure safe and smooth operations.

2. Inspect and Maintain Equipment Regularly

Before using any HDPE fusion machine, a thorough inspection of the machine and its components is crucial. This includes checking for any wear and tear on cables, fusion plates, and heating elements. Regularly servicing and calibrating the HDPE fusion equipment ensures it operates at optimal performance and minimizes the risk of malfunctions, which could cause delays or accidents.

3. Follow Manufacturer Instructions

Each HDPE fusion machine comes with a specific set of instructions that should be followed closely. These guidelines include recommended fusion temperatures, pressure settings, and fusion times. Adhering to these instructions not only ensures proper fusion but also contributes to the longevity of the machine and the integrity of the welded joints.

4. Ensure Workspace Safety and Ventilation

The workspace around the HDPE fusion machine must be kept clean, organized, and well-ventilated. A clean environment helps reduce the risk of accidents caused by tripping or falling over debris, while good ventilation ensures the safe release of any fumes produced during the fusion process. Additionally, it’s essential to have fire safety equipment, such as extinguishers, easily accessible to address any potential risks.

5. Only Qualified Operators Should Handle Fusion Equipment

Only trained and qualified personnel should operate the HDPE fusion machine. This ensures that the equipment is used correctly, minimizing safety hazards and improving weld quality. Qualified operators are familiar with the specific needs of HDPE pipe fusion, the potential risks, and how to troubleshoot common issues, thus preventing unnecessary downtime or equipment failure.

Final Thoughts on Ensuring Safe and Effective HDPE Fusion Machine Operations

The safe and effective operation of an HDPE fusion machine is essential for industries that rely on the durability and reliability of fused HDPE pipe joints. Whether you’re in the mining, oil and gas, municipal infrastructure, or any other sector using HDPE fusion equipment, adhering to proper safety protocols and best practices ensures both worker safety and the longevity of your pipeline systems.

An HDPE fusion machine contributes to achieving a high-quality weld. Following these guidelines not only minimizes the risk of accidents but also ensures that the HDPE pipe fusion process is efficient and cost-effective. By investing in well-maintained HDPE fusion equipment and properly trained operators, industries can safeguard their workforce, improve operational efficiency.

Prioritize safety, follow manufacturer guidelines, and always aim for the highest standards in HDPE pipe fusion to ensure your fusion projects are successful and sustainable.

Have questions or need expert guidance on your HDPE fusion projects? Contact us today to learn how our top-tier HDPE fusion machines and services can support your operations.