Floating pipes play a vital role in environmental and industrial applications by efficiently transporting fluids over water while maintaining buoyancy. They are commonly used in aquaculture, water treatment, and industrial operations. Choosing the right floating pipe is crucial for maximizing efficiency, ensuring regulatory compliance, and enhancing durability. This article explores the different applications, key factors to consider when selecting one, and essential maintenance practices to ensure optimal performance and longevity. Understanding these elements will help users make informed decisions and achieve better outcomes in their projects. Key factors include material properties, load capacity, environmental conditions, and compliance with industry standards.

Understanding Floating Pipes

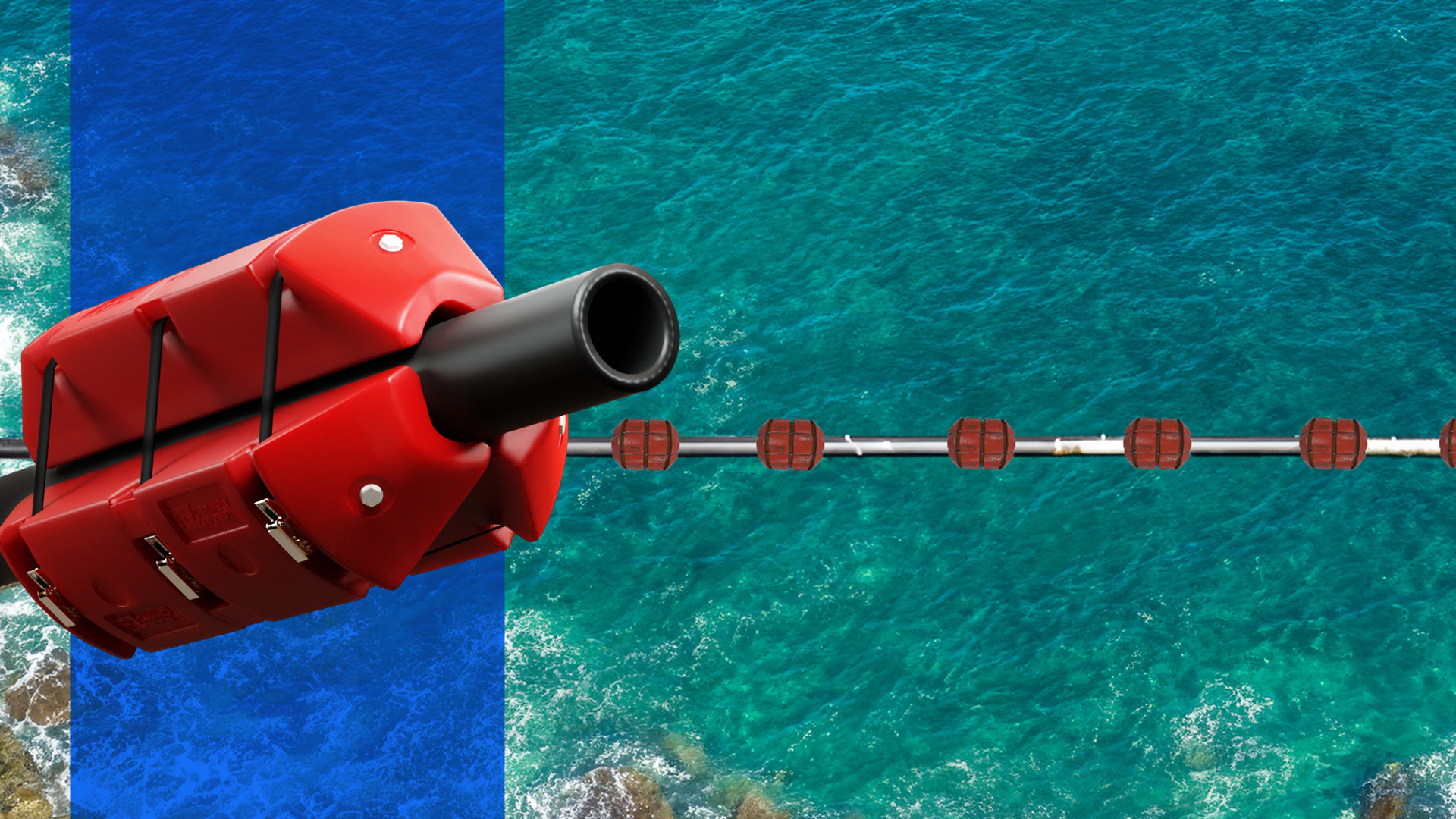

They are engineered to float on the surface of water, enabling the efficient transport of liquids in settings where traditional piping would be impractical or impossible. Common materials used in manufacturing include High-Density Polyethylene (HDPE) and PVC, which provide different benefits depending on the application.

These pipes’ primary function is to maintain buoyancy while facilitating the flow of liquids. Their versatility makes them suitable for a wide range of applications, from aquaculture and environmental management to industrial processes.

Applications

Environmental Applications

They are extensively used in various environmental projects, such as:

- Water Treatment and Aeration Systems: They are crucial in aeration basins, where they help introduce air into the water. This process promotes the breakdown of pollutants, making it easier to manage and treat wastewater.

- Aquaculture and Fish Farming: In aquaculture, They are utilized for feeding systems, oxygen supply, and waste management. They ensure a controlled environment for fish and other aquatic life, leading to healthier stocks and improved productivity.

- Pollution Control and Spill Response: They are vital for managing oil spills or chemical leaks. They help contain and redirect hazardous materials safely, minimizing environmental impact and aiding in cleanup efforts.

Industrial Applications

In the industrial sector, it serves various critical functions, including:

- Mining and Dredging Operations: These pipes transport slurries and other materials from underwater mining sites to processing facilities. Their buoyancy allows for easier maneuverability in challenging conditions.

- Oil and Gas Exploration: They are essential in offshore drilling operations. They facilitate the transport of hydrocarbons and other materials from submerged wells to surface facilities, and their design helps them withstand harsh marine environments.

- Construction and Infrastructure Projects: During construction projects involving water bodies, floating pipes streamline operations by facilitating the movement of materials and water. They can be particularly useful in managing sediment control and dewatering.

Key Factors to Consider

When choosing it, several crucial factors must be considered to ensure optimal performance:

Material Considerations

The material significantly impacts its durability and effectiveness. HDPE pipe floats are particularly popular due to their lightweight, high strength, and resistance to corrosion and UV exposure. Compared to other materials, HDPE offers superior flexibility and longevity, making it a preferred choice for many applications. PVC is also used but may provide a different level of performance under extreme conditions.

Load Capacity and Buoyancy Requirements

Different applications demand varying load capacities and buoyancy levels. Assessing the total weight of the pipe, fluids, and any additional equipment is essential for selecting a pipe that meets specific buoyancy needs. Proper calculations ensure that the floating pipe remains stable and functional in its intended environment.

Environmental Conditions

Environmental factors such as temperature, salinity, and UV exposure can significantly affect the performance of floating pipes. For instance, pipes used in marine environments must withstand saline water and harsh weather conditions. Therefore, selecting materials designed to endure specific environmental challenges is crucial for achieving longevity and effectiveness.

Compliance with Regulations and Standards

Many applications are subject to regulations that dictate material use, safety, and environmental impact. Ensuring that the selected floating pipe complies with industry standards is vital for avoiding legal complications and ensuring environmental protection. Compliance also guarantees that the materials used will not adversely affect the environment.

Types of Pipe Floats and Their Features

Various designs of pipe floats cater to different needs. Standard pipe floats, often made from buoyant materials, provide basic support. In contrast, HDPE pipe floats offer enhanced properties, such as greater resistance to impact and environmental degradation.

Comparison

- Standard Pipe Floats: Generally less expensive, these floats may offer different durability or resistance to harsh conditions. They are suitable for temporary projects or environments with less demand.

- HDPE Pipe Floats: Although more expensive, they provide superior performance, including greater buoyancy, flexibility, and resistance to chemicals and UV rays. They are ideal for long-term and demanding applications and ensure reliability over time.

Customization Options

Many manufacturers offer customization options to meet specific project needs. Whether adjusting the size, shape, or buoyancy properties, tailored solutions can enhance the functionality of floating pipes for particular applications. Customization can help optimize performance, ensuring the pipes meet the specific demands of the project.

Installation and Maintenance Tips

Proper installation and maintenance of them are essential for ensuring their longevity and performance.

Best Practices for Installation

- Site Assessment: Conduct a thorough site assessment to understand water conditions, potential obstacles, and environmental factors. Knowing the specific site characteristics will inform better installation practices.

- Secure Anchoring: Ensure that they are securely anchored to prevent movement caused by currents, wind, or other forces. Proper anchoring is vital for maintaining system integrity.

- Proper Alignment: Pipes should be aligned correctly to facilitate smooth fluid flow and prevent blockages. Misalignment can lead to reduced efficiency and increased wear.

Regular Maintenance

Routine maintenance checks can prevent issues and extend their lifespan.

- Inspect for Damage: Regularly check for signs of wear, such as cracks or degradation, especially in extreme conditions. Early detection can prevent costly repairs down the line.

- Clean and Clear: Remove debris or obstructions that may affect the flow of liquids or the buoyancy of the pipe. Keeping the pipes clean will enhance their performance.

- Monitor Performance: Monitor the pipe’s performance and make adjustments as needed to optimize functionality. Regular monitoring allows for timely interventions if problems arise.

Conclusion

Selecting the right floating pipe is crucial for both environmental and industrial applications. By considering material properties, buoyancy requirements, environmental conditions, and compliance standards, users can ensure optimal performance and longevity. Understanding the various types, along with best practices for installation and maintenance, further aids in making informed decisions.

As the demand for efficient fluid transport solutions continues to grow, investing time and resources into selecting the appropriate can lead to significant operational advantages and environmental benefits. For those navigating this selection process, consulting with experts can provide additional insights and guidance tailored to specific project needs. In a world where efficiency and sustainability are increasingly critical, making the right choice in floating pipes is an investment in the future.