In marine projects, from construction and dredging to infrastructure maintenance, managing and supporting pipelines and structures on or under the water presents unique challenges. Effective solutions are crucial for maintaining stability, safety, and efficiency. Among these solutions, HDPE (High-Density Polyethylene) pipe floats stand out due to their durability and performance. These floats play a pivotal role in enhancing marine projects, providing reliable support, and ensuring long-term success.

What Are HDPE Pipe Floats?

Definition and Purpose

They are specialized components designed to support and stabilize pipes and structures in aquatic environments. Made from high-density polyethylene, these floats are engineered to handle the harsh conditions of marine settings. They work by providing buoyancy to pipelines and other structures, preventing them from sinking or dragging along the seafloor, which is crucial for maintaining stability and functionality.Material Benefits

HDPE is a popular material for pipe floats due to its excellent properties. It is highly resistant to environmental factors such as UV radiation, saltwater, and temperature extremes. Unlike some materials that may degrade or corrode over time, HDPE maintains its integrity and performance, making it a cost-effective choice for long-term marine applications. The material’s flexibility and strength also allow for customization, ensuring that floats can be tailored to meet specific project requirements.

Applications of HDPE Pipe Floats in Marine Projects

Marine Construction

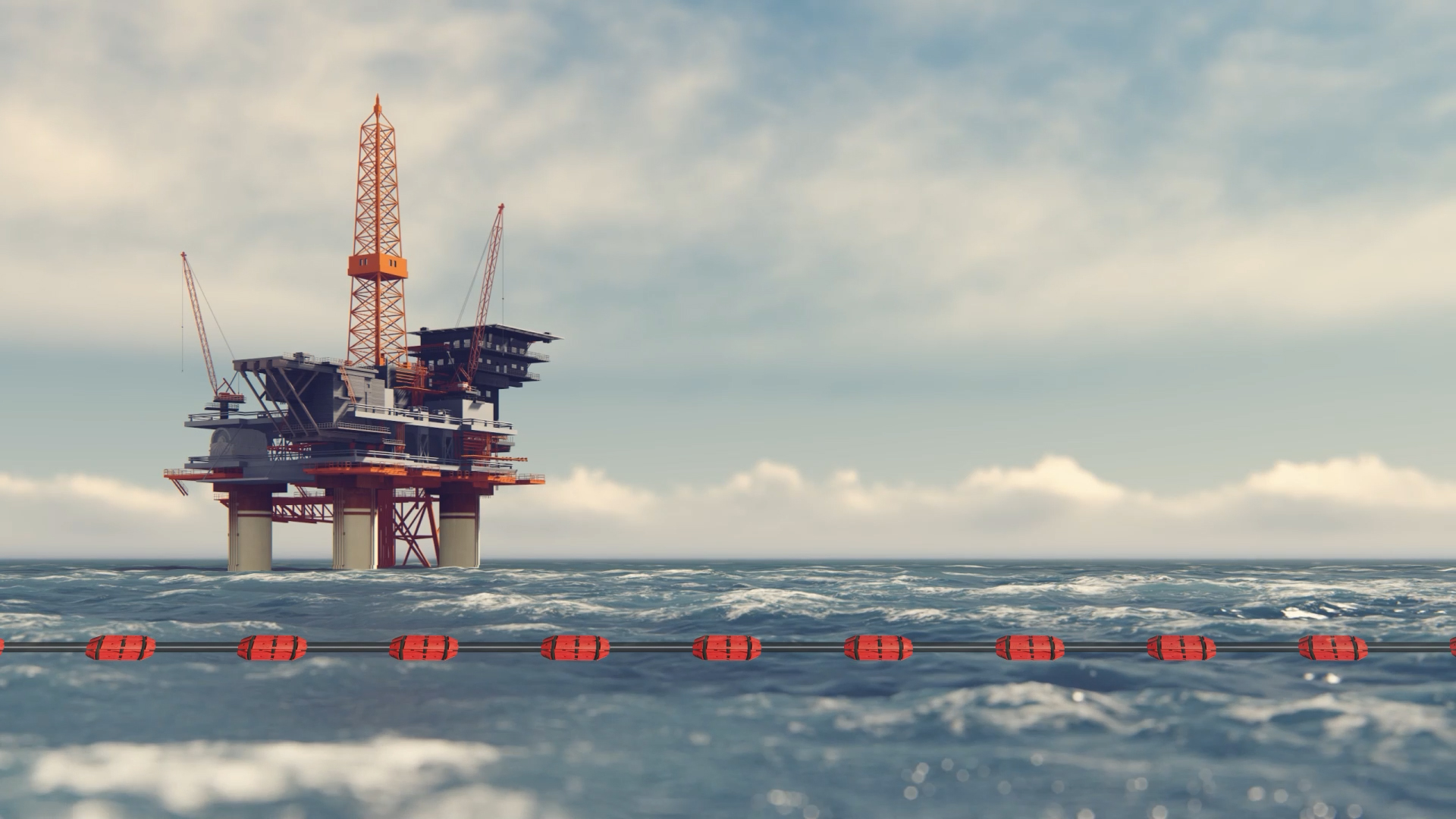

In marine construction, it supports floating docks, piers, and platforms. Its buoyant nature ensures that these structures remain stable and accessible, even in challenging conditions. By distributing the structure’s weight evenly and providing consistent support, it enhances safety and operational efficiency, making it an essential component in successful marine construction projects.Dredging Operations

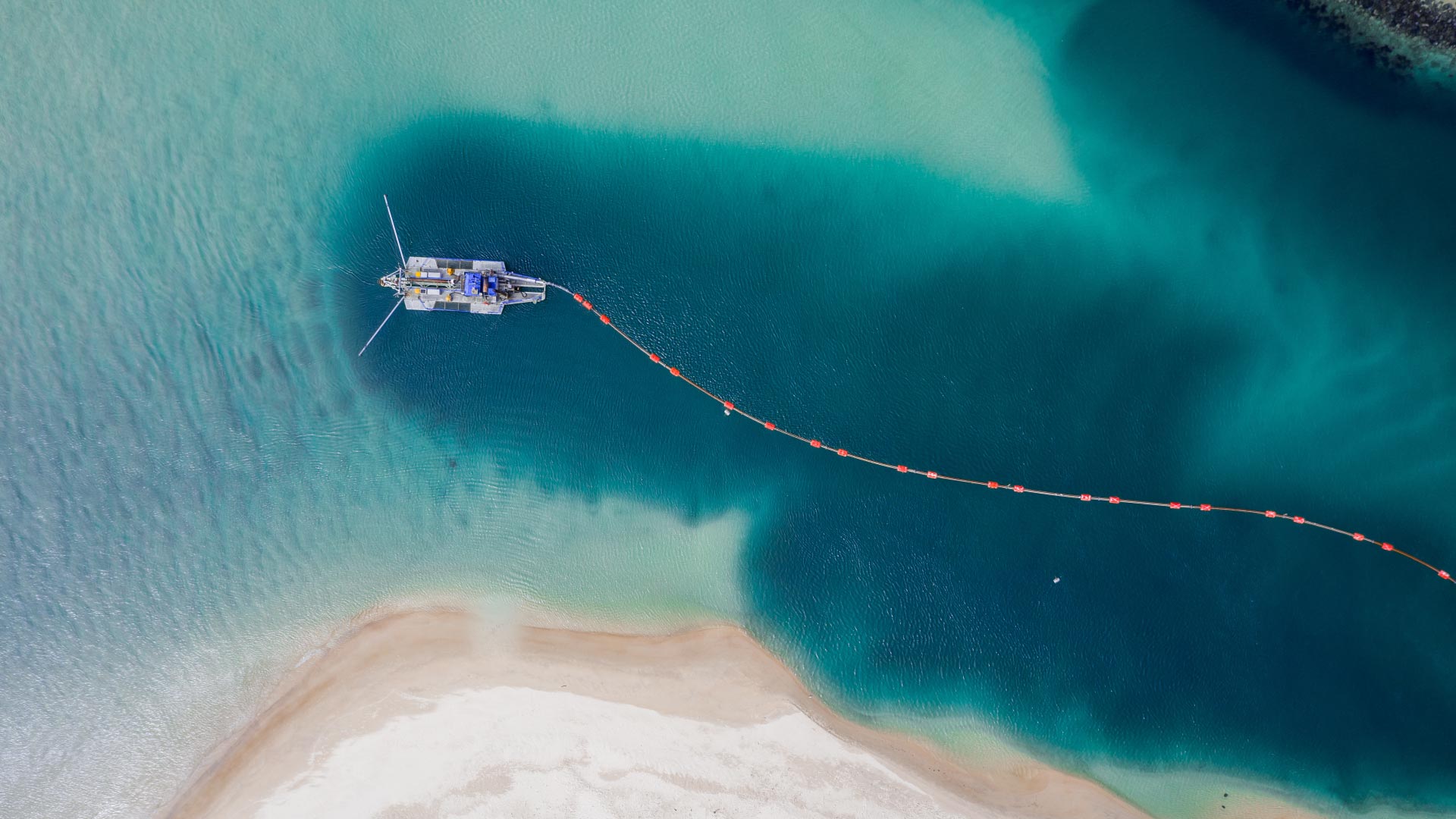

HDPE dredging pipe floats play a crucial role in dredging operations. They are used to support and stabilize dredging equipment, such as dredgers and pipeline systems. By keeping the equipment buoyant and properly aligned, these floats prevent damage and ensure smooth operation. Their ability to handle large volumes of sediment and resist wear and tear makes them ideal for demanding dredging environments.Infrastructure Maintenance

Another area where HDPE Pipes excel is maintaining and repairing underwater pipelines. They support pipelines during inspection and repair work, providing stability and preventing damage. This application is particularly important in ensuring the longevity and functionality of underwater infrastructure, helping to avoid costly repairs and downtime.

Types of HDPE Pipe Floats

Standard HDPE Pipe Floats

They are commonly used in various marine applications. They come in a range of sizes and configurations to suit different needs. These floats are designed to provide reliable buoyancy and support for typical marine projects, making them a versatile choice for many applications.Custom HDPE Pipe Floats

It offers tailored solutions for projects with unique requirements. These floats can be designed to meet specific load capacities, environmental conditions, and project constraints. Custom solutions ensure that the pipe floats provide optimal support and performance, addressing any special challenges presented by the project.Floating HDPE Pipe Supports

Floating HDPE pipe supports are another specialized type of pipe float. Unlike standard pipe floats, these supports are designed specifically to keep pipes elevated and stable while floating. They are particularly useful for applications where precise alignment and support are required, such as in complex marine construction or infrastructure projects.

Key Features and Benefits of Durable HDPE Pipe Floats

Durability and Longevity

One of their standout features is their durability. HDPE material is highly resistant to environmental factors like UV radiation, saltwater, and temperature fluctuations. This resistance ensures that it maintains its performance over time, providing long-lasting support and reducing the need for frequent replacements.Maintenance and Care

Maintaining HDPE Pipes is relatively straightforward. Regular inspections are important to check for signs of wear or damage. However, due to the material’s resilience, maintenance requirements are minimal compared to other materials.Cost-Effectiveness

While the initial investment in HDPE Pipes may be higher than some alternatives, the long-term benefits are substantial. Their durability and low maintenance needs result in lower overall costs. By reducing the frequency of replacements and repairs, HDPE Pipes offer a cost-effective solution for marine projects.

Best Practices for Using it in Marine Projects

Selection Criteria

Choosing the right one involves considering factors such as load capacity, environmental conditions, and specific project needs. Proper selection ensures that the floats will provide adequate support and performance throughout the project’s lifespan.Installation Tips

Correct installation is crucial for its effectiveness. Floats should be evenly spaced along the pipeline or structure to maintain balanced buoyancy. Proper installation also helps prevent issues such as uneven support or damage to the floats.Maintenance and Inspection

Regular inspections of them are essential to ensure continued performance. Check for any signs of wear, leaks, or damage. Addressing issues promptly helps maintain the efficiency and longevity of the pipe floats.

Future Trends and Innovations

Technological Advancements

The field of it is evolving with technological advancements. Innovations such as improved material formulations and design enhancements are set to further increase the efficiency and performance of pipe floats, further enhancing their suitability for various marine applications.Sustainability Considerations

There is a growing focus on sustainability in marine projects. Future trends include the development of eco-friendly practices that minimize environmental impact. HDPE’s recyclability and durability contribute to more sustainable project outcomes.

Conclusion

It plays a critical role in enhancing marine projects by providing reliable buoyancy and support. Their durability, ease of maintenance, and cost-effectiveness make them an invaluable asset in various applications, from construction and dredging to infrastructure maintenance. By leveraging advanced HDPE solutions, industries can achieve greater stability, efficiency, and sustainability in their marine projects. Evaluating your project needs and exploring them could be the key to successful and enduring marine operations.