Industrial hose supply stands at the core of operational reliability in demanding sectors such as oil and gas, chemicals, and mining. Far beyond being a simple connector in the production line, it serves as a lifeline for safely transferring volatile liquids, pressurized gases, and abrasive slurries under extreme conditions. In environments where even a minor failure can lead to downtime, safety hazards, or costly losses, the strength, flexibility, and engineering precision of industrial hoses define both performance and profitability. As industries push toward greater efficiency and sustainability, the focus on advanced, high-quality hose solutions has never been more critical.

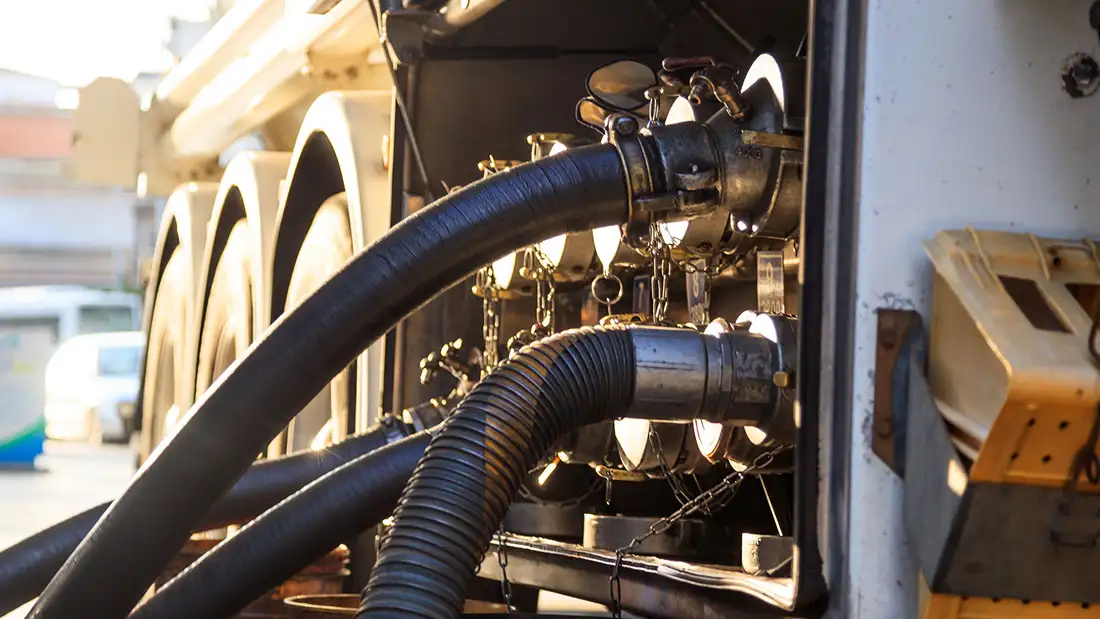

Industrial hose supply products are designed to withstand extreme temperatures, high pressures, and exposure to corrosive chemicals or abrasive substances. These hoses often face rugged environments where failure is not an option. For example, in the oil and gas industry, hoses used for fuel delivery or oil field service must endure oil-based chemicals, intense temperatures, and the constant wear of ongoing operations. In chemical plants, hoses must be chemically resistant to handle aggressive substances, while in mining, hoses are essential for slurry transfer and high-pressure water management.

In these heavy-duty industries, there’s no room for substandard equipment. High-performance industrial hose and supply solutions, sourced from trusted industrial hose suppliers, are critical to maintaining smooth operations and minimizing the risks associated with hose failure, such as spills, contamination, and costly downtime.

Industrial Hose Supply for Oil Industry Applications

Key Applications of Oil Hoses

In the oil industry, industrial hose supply is essential for the safe and efficient transportation of petroleum products, including crude oil, refined fuels, lubricants, and other hydrocarbons. These hoses are designed to withstand the extreme demands of the oil and gas industry, where reliability, performance, and safety are critical.

API-certified hoses are also essential for oilfield services. These hoses are engineered to meet industry requirements, ensuring they withstand the high-pressure, high-temperature conditions commonly encountered in oil extraction procedures. As a top industrial hose supplier, selecting hoses that meet these standards is critical to maintaining safe, effective operations.

Key Performance Features for Oil Hoses

The performance of industrial hose supply in the oil industry is defined by the hose’s ability to endure harsh environments without compromising safety or operational efficiency. High-quality industrial hoses are engineered with specific features to meet the demanding conditions of oilfield operations. Key performance attributes include:

- Oil Resistance: Durable materials with exceptional oil resistance, such as reinforced PVC, neoprene, or nitrile (NBR), must be used to manufacture oil hoses. By avoiding failure and reducing costly downtime, these materials ensure the hose retains its strength and integrity when exposed to petroleum-based pollutants. It’s critical to choose an industrial hose supply that provides sustained protection against the harmful effects of oil-based materials.

- Temperature and Abrasion Resistance: In oilfield operations, hoses frequently endure extreme temperatures and abrasive conditions. High-performance industrial hose and supply products are designed to withstand these factors, significantly reducing wear and tear while maintaining hose integrity over time. Industrial hoses that provide these features are essential to ensure minimal downtime and continuous operation, even in the most rugged environments.

- Antistatic Properties: Due to the flammability of many oil products, static discharge can pose a significant hazard. Industrial hose suppliers often provide oil hoses with antistatic properties to reduce the risk of sparks or explosions in hazardous environments. By integrating these safety features, suppliers ensure that their industrial hose supply products meet safety regulations and industry standards, making them ideal for high-risk oil operations.

- Chemical and Vapor Resistance: Oil hoses must withstand not just oils but also other dangerous substances and fumes. A reliable industrial hose and supply source will deliver hoses designed to withstand these materials, ensuring long-term, continuous performance. Hoses that can tolerate chemical and vapor exposure are useful for transporting gasoline, lubricants, and other volatile compounds, contributing to increased safety and operational dependability.

Choosing the Right Industrial Hose Supplier for Oil Hoses

When selecting an industrial hose supplier for oil-related applications, it’s important to choose a provider that offers hoses capable of handling the demanding conditions of the oil industry. Reliable industrial hose supply should offer hoses that meet API standards, which ensure performance and safety in oilfield environments.

Furthermore, selecting a supplier who can adapt hoses to fit your unique operational requirements is crucial. A reliable industrial hose and supply company will collaborate with you to deliver hoses with the appropriate length, diameter, and material properties, ensuring they meet the specific requirements of your application.

Industrial Hose Supply for Chemical Handling

The Role of Chemical Hoses in Industrial Operations

Industrial hose supply are essential for maintaining safety and operational effectiveness in sectors where corrosive and dangerous chemicals are transported. Chemical hoses are designed to work with substances such as alkalis, acids, solvents, and petroleum-based products. These hoses are essential for preserving safety and legal compliance in industrial, chemical processing, and even pharmaceutical facilities.

Hoses used in the chemical industry must be resistant to the corrosive compounds being transported. Whether in chemical manufacturing plants or fertilizer facilities, industrial hose and supply firms must provide hoses that are designed for reliability, flexibility, and safety. In many businesses, failure is not an option, since leaks or hose failures can result in major accidents, costly shutdowns, and regulatory penalties.

Key Features of Chemical Hoses

For industries handling chemicals, industrial hoses must be designed with specialized materials to ensure safety and durability. The key features of high-quality chemical hoses include:

- Chemical Resistance: Industrial hoses used in chemical applications must be lined with materials like EPDM, PTFE, or UHMWPE, which are specifically designed to resist a wide range of corrosive chemicals. These materials ensure the hose does not degrade or react with the chemicals being transported, preventing costly downtime and safety incidents.

- Temperature and Pressure Resistance: Many chemicals are transferred at extreme temperatures or under high pressure. Industrial hose supply companies offer hoses made from heat-resistant materials to ensure that hoses maintain flexibility and strength under such conditions.

- Reinforced Construction:To withstand the mechanical pressures of chemical transfer, hoses are frequently reinforced with numerous layers, such as fabric or steel braiding, to avoid kinks, abrasions, and rupture. This reinforcement is critical for the structural integrity of hoses, particularly in high-pressure applications.

- Compliance and Safety Standards: Chemical hoses must comply with industry safety standards such as OSHA, ANSI, and ASTM. A trusted industrial hose supplier will offer hoses that meet or exceed these standards to ensure safe, compliant operations and reduce the risk of hazardous material spills or leaks.

Selecting the Right Industrial Hose Supplier for Chemical Hoses

To ensure your chemical hoses meet your business’s exacting standards, you must select the best industrial hose supply partner. To ensure a long service life and dependable performance, a trustworthy industrial hose supply partner should offer hoses constructed from materials specifically suited to handling harsh chemicals.

Additionally, working with an expert supplier allows you to receive professional guidance on selecting the ideal hoses for your needs. The ideal industrial hose supply company will offer solutions specifically designed to meet your operating needs, whether you require hoses with special fittings or in specific lengths.

Industrial Hose Supply for Mining Applications

Key Applications of Hoses in Mining

In the mining industry, industrial hoses play an essential role in handling abrasive materials, slurry, fuel, and water. Industrial hose supply is critical in ensuring that these materials are transported safely and efficiently in one of the harshest operating environments.

Industrial hose and supply companies offer hoses specifically designed for mining applications, ensuring reliability and durability even in the most demanding environments. Fuel delivery hoses used to refuel mining machinery also require specialized materials to withstand the harsh conditions found in mines and on construction sites.

Durability & Safety Considerations for Mining Hoses

Mining hoses are constantly exposed to rough, abrasive conditions, making durability and safety a top priority. The key durability and safety features of mining hoses include:

- Abrasion Resistance: Mining hoses are often exposed to abrasive materials, including slurry, rock, and dust. Industrial hose suppliers offer hoses made from wear-resistant materials, such as synthetic rubber or polyurethane, to extend the hose’s lifespan and reduce downtime caused by damage.

- Pressure Resistance: Mining operations often involve high-pressure slurry transfer and dewatering. Industrial hoses used in these applications must be designed to handle the high-pressure demands of these systems. A reputable industrial hose supply company will provide hoses reinforced with layers of fabric or steel braids to handle high-pressure environments safely.

- Temperature Resistance: Mining operations often take place in extreme temperatures, with hoses exposed to both heat and cold. Industrial hose and supply companies offer mining hoses constructed from materials that maintain their flexibility and strength even in extreme conditions.

- Chemical Resistance: Many mining processes involve the use of chemicals or reagents that can be highly corrosive. Industrial hose supply must provide hoses that can resist these chemicals, ensuring that the hoses remain safe and functional throughout their service life.

Choosing the Right Industrial Hose Supplier for Mining

For mining operations, choosing the best industrial hose supply company is essential to maintaining operational efficiency and safety. To survive the severe conditions inherent to mining locations, mining hoses must meet specific performance requirements, such as high pressure and abrasion resistance.

Mining operators may make sure they have hoses that are precisely suited to their requirements by working with a credible industrial hose and supply company. Mining companies can increase safety, reduce downtime, and ultimately boost production and efficiency with the right hoses.

Conclusion: The Critical Role of Industrial Hose Supply in Heavy-Duty Industries

Industrial hoses are essential components in the oil, chemical, and mining sectors, enabling the safe, efficient, and reliable transfer of various materials under extreme conditions. From transporting petroleum products in oilfields to handling hazardous chemicals in processing plants and managing abrasive slurries in mining operations, industrial hose supply plays a pivotal role in maintaining operational continuity and safety.

As industries face increasing demands for performance, durability, and compliance, selecting the right industrial hose supplier becomes crucial. A reliable supplier not only offers high-quality hoses that meet industry standards but also provides the necessary technical expertise to ensure the best fit for specific applications. Whether it’s rubber or metal hoses, flexible or rigid, each type is designed to meet the unique challenges of heavy-duty environments.

Investing in premium industrial hose and supply solutions results in reduced downtime, lower maintenance costs, and enhanced operational safety, leading to a strong return on investment (ROI). For procurement heads, engineering managers, contractors, and government buyers, choosing the right industrial hoses is more than just a purchase; it’s a strategic decision that directly impacts the efficiency, safety, and profitability of industrial operations.

By working with an experienced industrial hose supplier and ensuring that hoses meet the rigorous demands of your industry, you can rest assured that your operations will run smoothly and safely, even in the most challenging conditions.