Floating hoses have become indispensable in various industrial sectors due to their flexibility, durability, and efficiency in transporting materials. These hoses are designed to float on water surfaces, making them ideal for applications where traditional hoses or pipelines would be impractical. From dredging to mining, floating hoses enhance operational efficiency and reduce costs. This blog explores the numerous benefits of using floating hoses in industrial applications, highlighting their versatility, durability, and impact on various industries. You can visit Pipe and Hose Floats for more information on floating hoses.

Understanding Floating Hoses

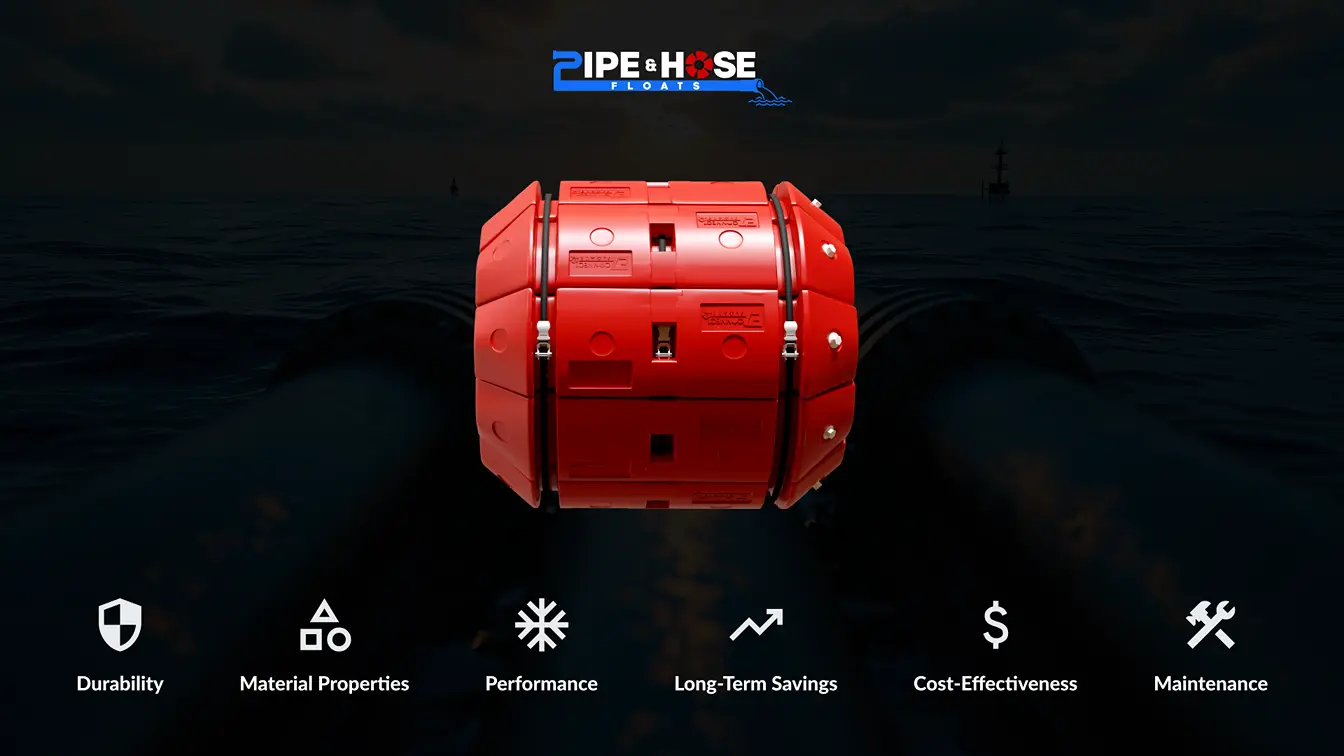

Floating hoses are specialized hoses designed to remain buoyant on water surfaces while transporting liquids, slurries, or other materials. They consist of several key components: a durable outer cover to protect against external damage, an inner lining resistant to transporting materials, and a flotation material to ensure the hose stays afloat.

At Pipe and Hose Floats, you can find a variety of floating hoses, including single and double carcass hoses. Single carcass hoses are typically used in less demanding environments, while double carcass hoses offer added protection and durability, making them suitable for more rigorous conditions. Reinforced with steel or other strong materials, armored hoses protect against abrasion and impact.

Versatility of Floating Hoses

One of the primary advantages of floating hoses is their versatility. They can be used in various industrial applications, including dredging, mining, oil and gas, and marine operations. Their ability to transport multiple materials, such as water, oil, chemicals, and slurries, makes them indispensable in many industries.

Floating hoses can quickly adapt to different terrains and water conditions, ensuring uninterrupted operations. This adaptability is particularly beneficial in environments where the water level or terrain changes frequently. For instance, floating hoses transport sediment from the dredging site to a disposal or reclamation area in the dredging industry. Their ability to float on water ensures that the sediment is efficiently moved without sinking, which can obstruct the dredging process. Floating hoses also allow for flexible positioning of dredging equipment, enhancing operational efficiency.

At Pipe and Hose Floats, you can find versatile floating hose solutions, as well as classic industrial hose floats tailored to meet the specific needs of different industries. Their products are designed to offer maximum efficiency and flexibility, ensuring optimal performance in various applications.

Flexibility and Efficiency

Floating hoses are renowned for their flexibility, making them easy to install and reposition as needed. This flexibility allows them to handle changing water levels and environmental conditions, ensuring continuous operation. In industrial applications, this adaptability translates to improved operational efficiency and productivity.

For example, floating hoses are essential for transporting slurry and tailings in mining operations. They provide a reliable solution for moving materials over long distances, and in challenging terrains are better than pipe and their accompanying pipe floats. Their durability ensures they can handle the abrasive nature of mining slurries, reducing downtime and maintenance costs.

At Pipe and Hose Floats, you can find floating hoses designed to offer maximum flexibility and efficiency. Their products are engineered to withstand the harsh conditions of various industrial applications, ensuring reliable performance and minimal maintenance.

Case Study: Mining Operation in Australia

An Australian mining company implemented floating hoses from Pipe and Hose Floats to transport slurry from the mine to the processing plant. The hoses’ ability to handle abrasive materials without frequent repairs or replacements resulted in substantial cost savings. The company reported improved productivity and reduced operational costs, highlighting the benefits of using floating hoses in mining applications.

Durability and Longevity

Floating hoses are constructed from robust materials designed to withstand harsh environments. They resist UV radiation, abrasion, and chemical exposure, ensuring a long service life even in the most demanding conditions. This durability translates to fewer replacements and lower maintenance costs.

At Pipe and Hose Floats, the focus is on providing high-quality, durable floating hoses that can handle the most demanding industrial applications. Their products are made from premium materials to ensure longevity and reliable performance.

Maintenance Practices to Extend Lifespan

Proper maintenance is critical to extending the lifespan of floating hoses. Here are some best practices:

- Regular Inspections: Conduct regular inspections early to identify and address any signs of wear or damage. This includes checking for abrasions, leaks, and buoyancy issues.

- Proper Storage: When not used, store hoses in a cool, dry place away from direct sunlight. Proper storage prevents premature aging and damage.

- Cleaning: Clean the hoses after use, especially when transporting abrasive or corrosive materials. This prevents residue buildup and prolongs the hose’s lifespan.

By following these maintenance practices, industries can maximize the durability of floating hoses, ensuring long-term cost savings and reliable performance.

Cost-Effectiveness

While the initial investment in floating hoses may be higher than traditional hoses or pipelines, their long lifespan and low maintenance requirements result in significant cost savings over time. The reduced need for repairs and replacements means lower operational costs and improved efficiency.

A cost-benefit analysis using data from the Pipe and Hose Floats site shows that investing in high-quality floating hoses can lead to substantial long-term savings. The durability and reliability of these hoses reduce the frequency of replacements and repairs, resulting in lower maintenance costs and increased operational efficiency.

Impact on Overall Operational Budget

Floating hoses can positively impact the overall operational budget by reducing the need for frequent hose replacements and minimizing maintenance downtime. The long-term cost savings and improved efficiency make floating hoses a cost-effective solution for various industrial applications.

Safety and Environmental Benefits

Floating hoses offer enhanced safety due to their reduced risk of leaks and spills. Their robust construction and reliable performance ensure that materials are transported safely and efficiently, minimizing the risk of accidents.

Another significant benefit of using floating hoses is environmental protection. Floating hoses help industries comply with environmental regulations and reduce their ecological footprint by minimizing material loss and ensuring efficient transport.

At Pipe and Hose Floats, safety and environmental protection are top priorities. Their products are designed to meet the highest safety standards and minimize environmental impact, ensuring that industries can operate responsibly and sustainably.

Conclusion

Floating hoses offer numerous benefits in industrial applications, from their versatility and flexibility to their durability and cost-effectiveness. They play a crucial role in dredging, mining, oil and gas, and marine operations, enhancing efficiency and reducing operational costs. By selecting suitable hoses for the job and following proper maintenance practices, industries can maximize the advantages of floating hoses, ensuring smooth and efficient material transfer operations.

For more information and to explore a comprehensive range of floating hoses, visit Pipe and Hose Floats. Discover how their high-quality products can enhance your industrial operations and provide long-term cost savings.