HDPE pipe floats have become a cornerstone in various industrial applications, providing essential support and efficiency in transporting materials across water bodies. High-Density Polyethylene (HDPE) pipe floats are known for their durability, buoyancy, and versatility, making them an indispensable tool in dredging, mining, oil and gas, marine operations, and agriculture. This blog explores the role of HDPE pipe floats, their key features, applications, benefits, and the technological advancements that make them a preferred choice for industrial use. For more information, visit Pipe and Hose Floats.

What Are HDPE Pipe Floats?

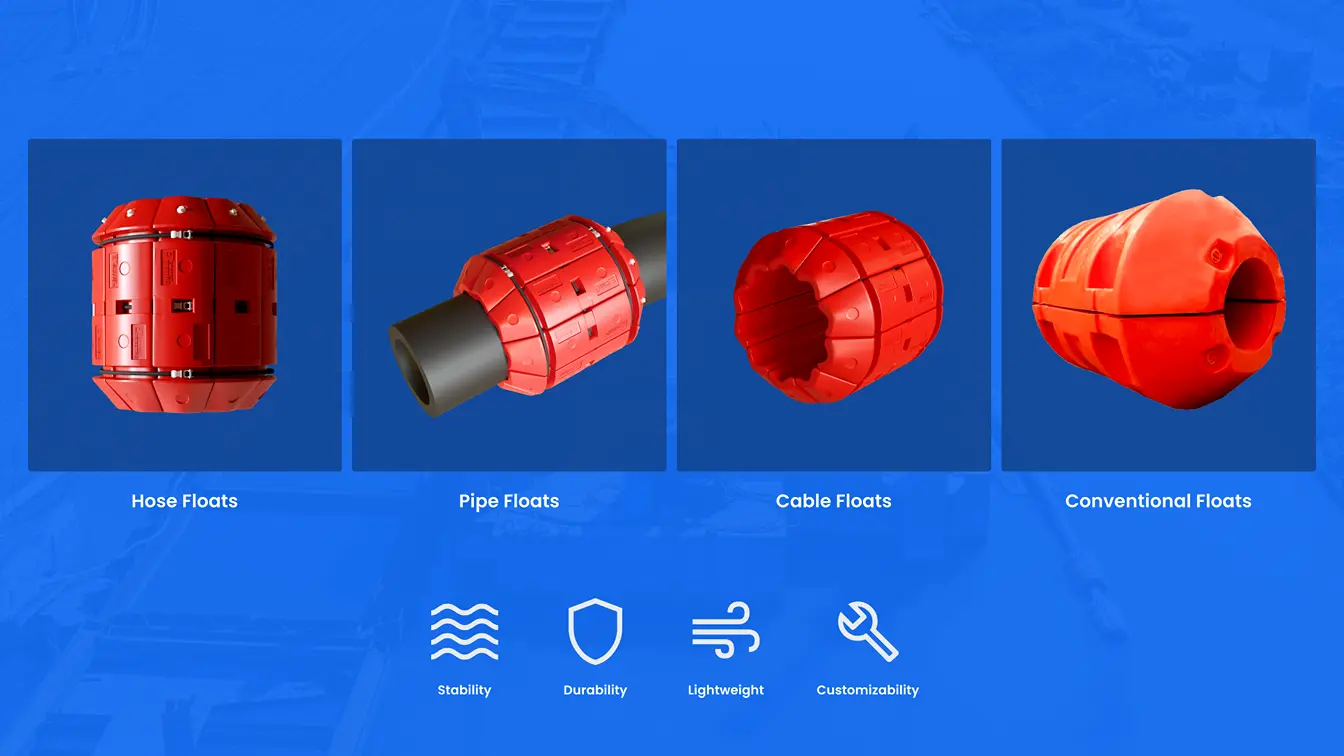

HDPE pipe floats are devices designed to provide buoyancy to pipes and hoses used in various industrial applications. Made from High-Density Polyethylene, these floats are robust and lightweight, offering a perfect balance of strength and flexibility. The primary function of HDPE pipe floats is to keep the pipes and hoses afloat, ensuring smooth and efficient transport of materials over water.

The structure of an HDPE pipe float typically includes an outer shell made of HDPE and a core filled with buoyant material. This design ensures the floats can withstand harsh environmental conditions while providing reliable support to the pipes and hoses.

Key Features of HDPE Pipe Floats

HDPE pipe floats come with several key features that enhance their performance and reliability in industrial applications:

Buoyancy and Stability:

HDPE pipe floats are designed to provide optimal buoyancy, ensuring that the pipes and hoses remain afloat even under heavy loads. Their stability minimizes the risk of tilting or capsizing, which can disrupt operations.

Durability and Resistance to Environmental Factors:

HDPE ensures that the pipe floats resist UV radiation, chemicals, and abrasion. This resistance provides a long lifespan and reduces the need for frequent replacements.

Lightweight and Ease of Handling:

HDPE pipe floats are lightweight, making them easy to handle and transport. This feature simplifies installation and reduces the overall operational burden.

Customizability:

HDPE pipe floats can be customized to meet the specific requirements of different industries. This customization includes sizes, shapes, and buoyancy levels to ensure optimal performance.

Applications of HDPE Pipe Floats

HDPE pipe floats are used in a variety of industrial applications due to their versatility and reliability:

Dredging Industry:

HDPE pipe floats are crucial in transporting dredged materials from the seabed to disposal or reclamation sites in dredging operations. Their buoyancy ensures efficient material transport without sinking, enhancing operational efficiency.

Mining Industry:

HDPE pipe floats are essential for handling slurry and tailings. Their durability and resistance to abrasion make them ideal for transporting these abrasive materials over long distances.

Oil and Gas:

The oil and gas industry relies on HDPE pipe floats for offshore and onshore operations. Offshore, they facilitate oil transport between vessels and storage facilities, while onshore, they ensure the safe transport of oil and gas from extraction sites to processing plants.

Marine Operations:

HDPE pipe floats are used for material transfer and cargo handling in marine and port operations. Their stability and durability make them suitable for the dynamic environment of ports and harbors.

Agricultural and Irrigation Systems:

HDPE pipe floats are also used in farming and irrigation systems to ensure efficient water transport. Their lightweight nature and durability make them ideal for various irrigation setups.

Benefits of Using HDPE Pipe Floats

The use of HDPE pipe floats in industrial applications offers several significant benefits:

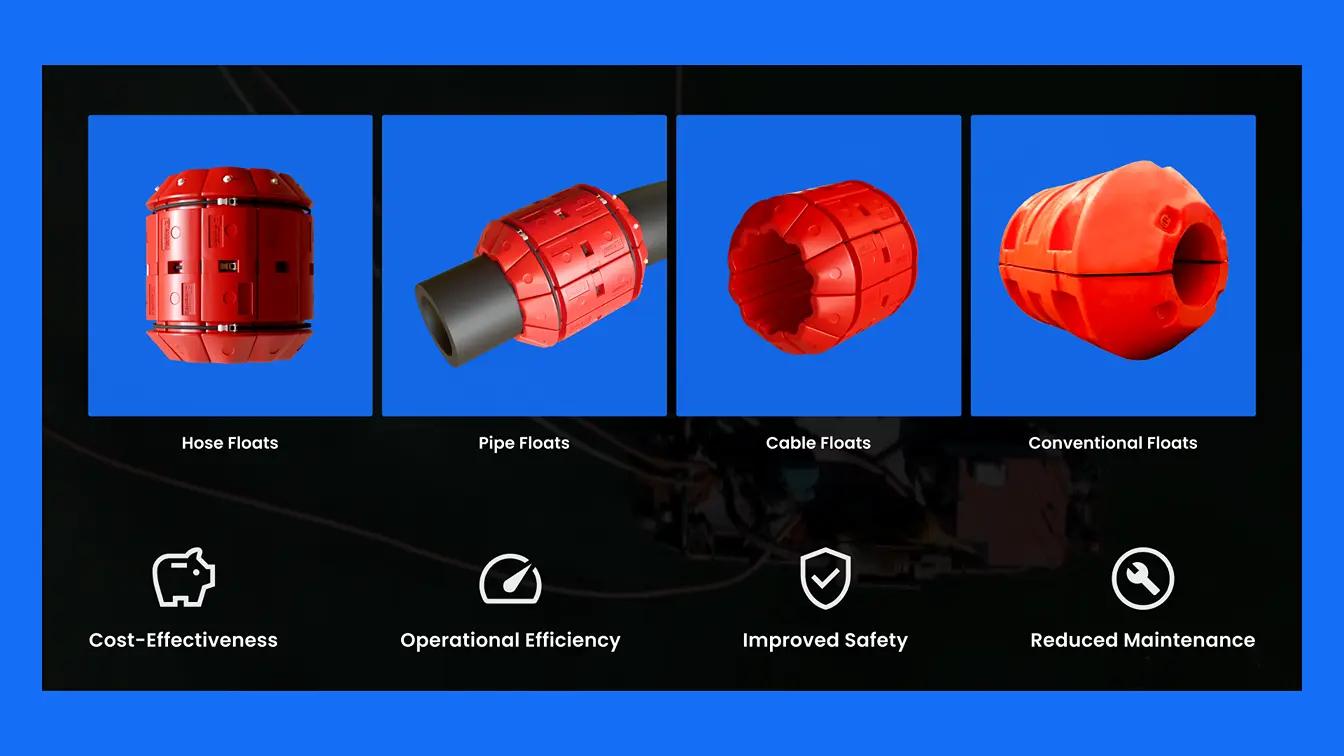

Cost-Effectiveness and Long-Term Savings:

HDPE pipe floats have a long lifespan and require minimal maintenance, resulting in substantial cost savings over time. The reduced need for replacements and repairs offsets the initial investment.

Enhanced Operational Efficiency and Productivity:

The lightweight and durable nature of HDPE pipe floats enhances operational efficiency by ensuring reliable and uninterrupted material transport. This efficiency translates to increased productivity and reduced operational downtime.

Improved Safety and Environmental Protection:

HDPE pipe floats minimize the risk of leaks and spills, ensuring safe material transport. Their robust construction and resistance to environmental factors also help protect the environment by reducing the risk of contamination.

Reduced Maintenance and Downtime:

HDPE pipe floats’ durability and resistance to wear and tear require less frequent maintenance, resulting in reduced downtime and uninterrupted operations.

Technological Advancements in HDPE Pipe Floats

Recent technological advancements have further enhanced the performance and reliability of HDPE pipe floats:

Integration of Smart Technologies:

Modern HDPE pipe floats can be equipped with sensors and monitoring systems to provide real-time data on their performance and condition. This data helps in proactive maintenance and ensures optimal operation.

Innovations in Design and Materials:

Continuous research and development have led to innovations in the design and materials used in HDPE pipe floats. These innovations include enhanced buoyancy materials and more robust outer shells, further increasing their durability and performance.

Enhanced Manufacturing Processes:

Advances in manufacturing processes have produced higher-quality HDPE pipe floats with consistent performance. These processes ensure better control over the materials and construction, resulting in more reliable products.

Case Studies and Real-World Examples

Dredging Project in the Netherlands:

In a major dredging project in the Netherlands, HDPE pipe floats from Pipe and Hose Floats were used to transport dredged material from the seabed to a reclamation site. Due to the robust construction and buoyancy of the HDPE floats, the project saw significant improvements in efficiency and a reduction in maintenance costs.

Mining Operation in Australia:

An Australian mining company implemented HDPE pipe floats to transport slurry from the mine to the processing plant. The floats’ ability to handle abrasive materials without frequent repairs resulted in substantial cost savings and improved productivity.

Oil and Gas Industry Example:

HDPE pipe floats have facilitated oil transport in offshore environments in the oil and gas sector. Their resistance to harsh sea conditions and chemical exposure has proven invaluable, ensuring reliable and safe operations.

Marine Operations in the United States:

A port in the United States adopted HDPE pipe floats for cargo handling operations. The floats provided stability and durability, allowing for efficient material transfer and reducing operational downtime.

Selecting the Right HDPE Pipe Floats

When selecting HDPE pipe floats, it is essential to consider several factors to ensure optimal performance:

Material Compatibility: Ensure that the materials used in the pipe floats are compatible with the substances being transported. This compatibility is crucial for maintaining the integrity of the floats and preventing damage.

Environmental Conditions: Consider the conditions where the pipe floats will be used. HDPE pipe floats resist UV radiation, chemicals, and abrasion, making them suitable for harsh environments.

Operational Requirements: Evaluate the specific operational requirements, such as the hose’s length and diameter, the pressure it needs to withstand, and the expected flow rate. Choosing the correct float for the application will enhance efficiency and reduce maintenance needs.

Conclusion

HDPE pipe floats play a crucial role in enhancing the efficiency and reliability of floating hose technology in various industrial applications. Their durability, buoyancy, and resistance to environmental factors make them an ideal choice for industries ranging from dredging to mining, oil and gas, marine operations, and agriculture. By understanding the benefits and advancements of HDPE pipe floats, industries can optimize their operations and achieve significant cost savings.

For more information and to explore a comprehensive range of HDPE pipe floats, visit Pipe and Hose Floats. Discover how their high-quality products can meet your industrial needs and improve operational efficiency.