In industrial applications, buoyancy solutions are crucial in ensuring the efficient and safe transportation of materials across water bodies. Industries such as dredging, oil and gas, environmental management, and mining rely heavily on these buoyancy solutions to maintain operational efficiency. The most commonly used buoyancy devices are hose floats, HDPE pipe floats, and floating pipes. These innovative tools offer numerous benefits, including durability, cost-efficiency, and ease of use, making them indispensable in various industrial applications.

Understanding Hose Floats and HDPE Pipe Floats

Definitions and Differences

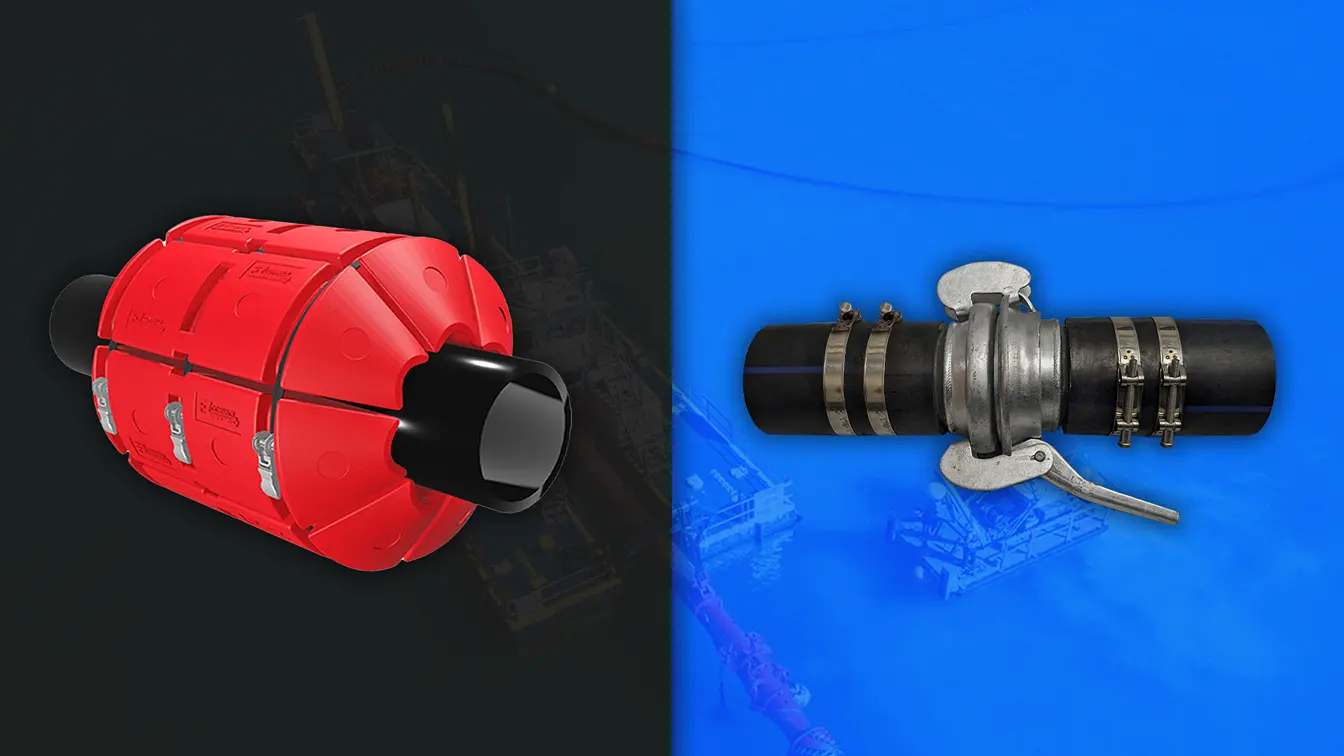

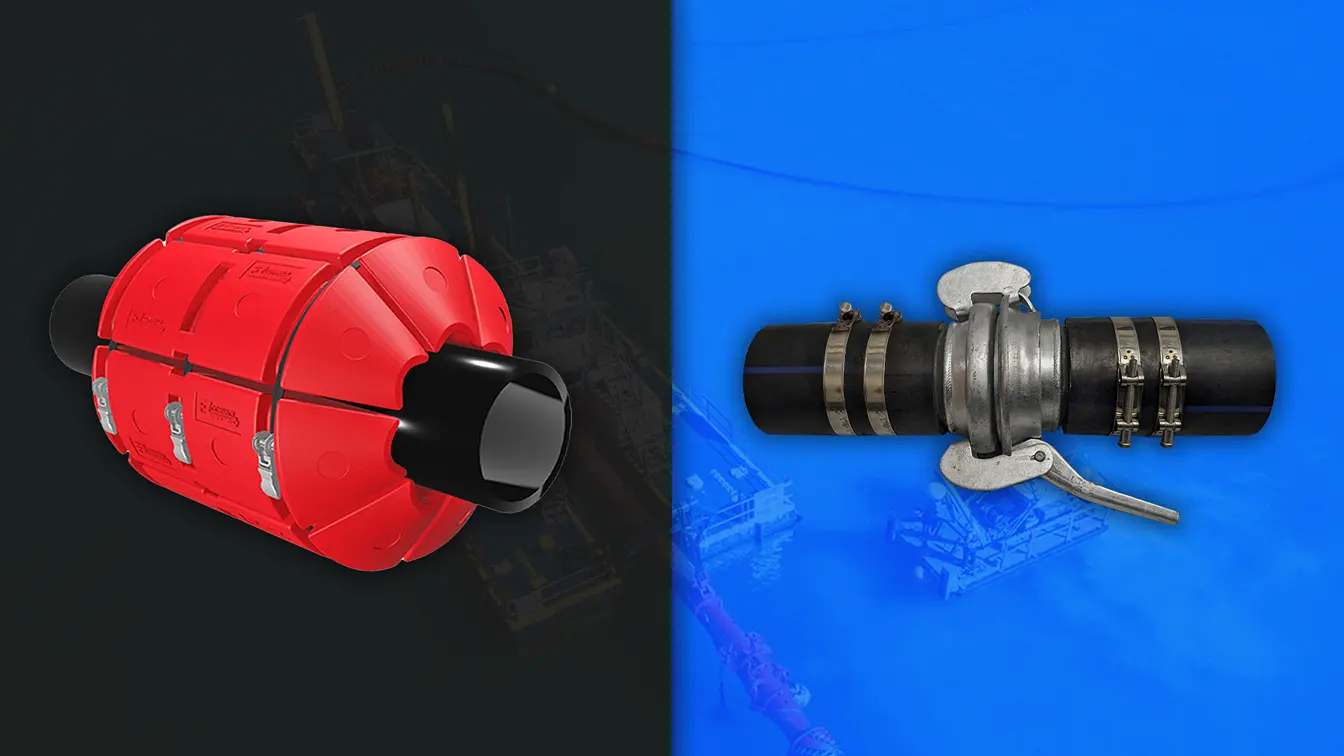

Hose Floats are buoyant devices designed to support and stabilize hoses and pipelines used in various industrial processes. They are typically made from high-density polyethylene (HDPE) or other durable materials and engineered to withstand harsh environmental conditions. Hose floats keep hoses afloat, preventing them from sinking, becoming entangled, or being damaged. On the other hand, HDPE Pipe Floats are specifically designed to support HDPE pipes. These floats are made from the same material as the pipes they support, ensuring compatibility and longevity. HDPE pipe floats keep the pipes buoyant, allowing for smooth and efficient transportation of materials across water bodies. The primary difference between hose floats and HDPE pipe floats lies in their application. While hose floats support flexible hoses, HDPE pipe floats support rigid HDPE pipes. Both floats have the same fundamental purpose: to provide buoyancy and stability to the pipes or hoses they support.

Benefits

Durability

One of the most significant advantages of hose and HDPE pipe floats is their durability. Made from high-quality materials such as HDPE, these floats are designed to withstand harsh environmental conditions, including exposure to UV rays, salt water, and chemicals. This durability ensures that the floats can be used in various industrial applications without deteriorating or losing buoyancy. HDPE is particularly resistant to abrasion and impacts, making it ideal for floats that endure rough handling and challenging environments.Cost-Efficiency

Hose and HDPE pipe floats are cost-efficient solutions for hose and pipe buoyancy. Their long lifespan and minimal maintenance requirements translate to reduced operational costs for industries. Additionally, the ease of installation and removal further contributes to their cost-efficiency, reducing labor costs and downtime. In sectors where operational efficiency and budget management are crucial, the cost savings offered by these floats can be significant.Ease of Use

Another notable benefit of hose and HDPE pipe floats is their ease of use. These floats are designed for quick and straightforward installation, allowing industry personnel to deploy them rapidly and efficiently. The lightweight nature of HDPE material makes handling and transportation easy, further enhancing their usability. This user-friendly design ensures that the floats can be installed and maintained with minimal effort, even in remote or challenging locations.Environmental Sustainability

HDPE and hose floats are durable, cost-efficient, and environmentally sustainable. HDPE is a recyclable material, meaning that once the floats reach the end of their lifespan, they can be recycled and repurposed, reducing environmental impact. This sustainability aspect is increasingly important as industries strive to adopt greener practices and minimize their ecological footprint.

Applications

Dredging

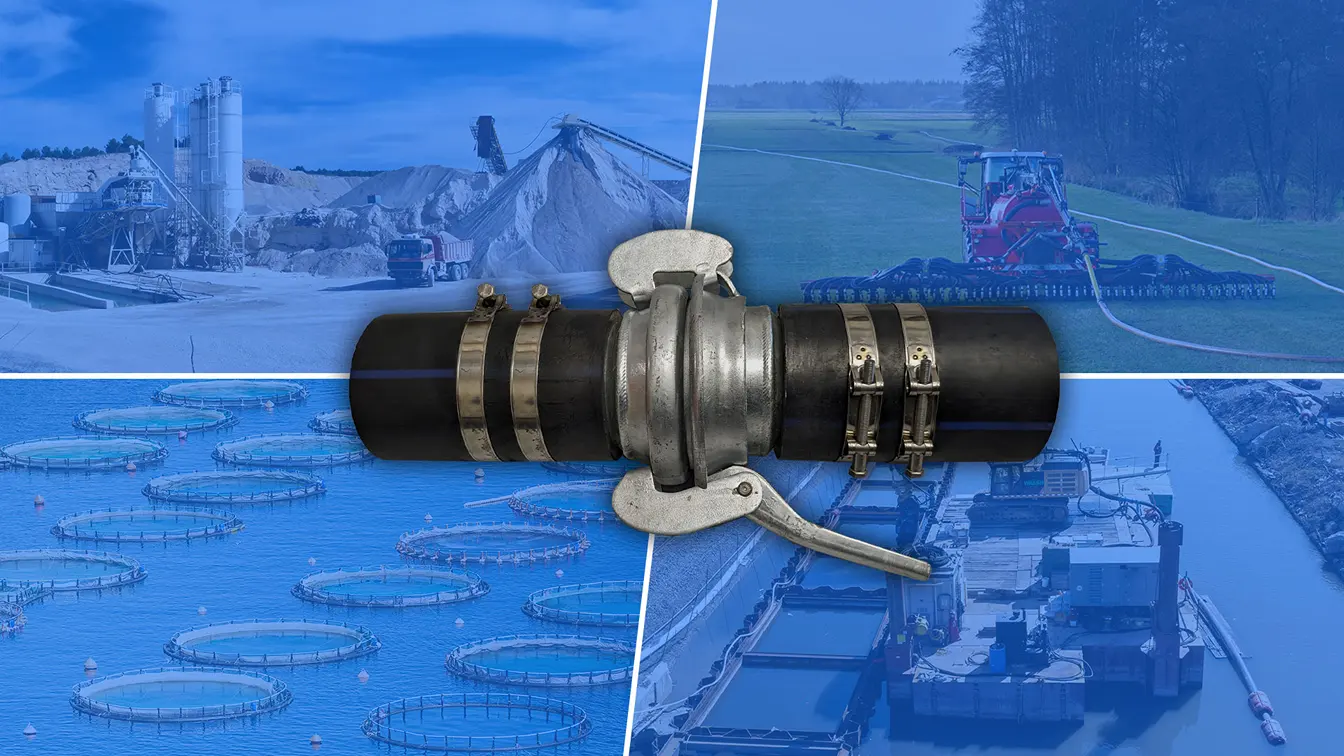

In the dredging industry, hose and HDPE pipe floats are essential for maintaining the buoyancy of dredging hoses and pipelines. Dredging involves removing sediments and debris from the bottom of water bodies, and using floating hoses and pipes ensures that the materials are transported efficiently. Hose floats prevent hoses from sinking and becoming entangled, while HDPE pipe floats keep the pipelines stable and buoyant, ensuring smooth operation. Using hose and HDPE pipe floats in dredging operations allows for continuous and effective dredging processes. These floats help maintain a consistent flow of dredged materials, preventing interruptions and ensuring the operation can proceed without delays. This consistency is crucial for large-scale dredging projects that require precise timing and coordination.Oil & Gas

The oil and gas industry relies heavily on hose and HDPE pipe floats. In offshore drilling and transportation, maintaining the buoyancy of hoses and pipelines is critical to prevent damage and ensure the efficient flow of oil and gas. These floats provide the necessary support to keep the hoses and pipes afloat, reducing the risk of leaks, spills, and other operational issues. Hose and HDPE pipe floats are essential in harsh marine environments where rough seas and strong currents pose significant challenges. Keeping the hoses and pipes buoyant, these floats help to mitigate the risks associated with offshore oil and gas operations, ensuring the safety and efficiency of the processes involved. Additionally, hose floats and HDPE pipe floats can enhance the longevity of the hoses and pipes, reducing the frequency of replacements and associated costs.Environmental Management

Environmental management projects, such as oil spill cleanup and water treatment, utilize hose and HDPE pipe floats to maintain the buoyancy of hoses and pipelines used in these processes. By keeping the hoses and pipes afloat, these floats facilitate the efficient removal of contaminants and the transport of treated water, contributing to the overall success of environmental management efforts. In oil spill cleanup operations, for example, hose and HDPE pipe floats enable the swift and effective deployment of skimmers and other equipment to remove oil from the water surface. Quickly responding to oil spills is crucial for minimizing environmental damage and protecting marine ecosystems. Furthermore, in water treatment projects, these floats ensure the necessary equipment can be deployed and operated effectively, providing a clean water supply to affected areas.Mining and Construction

HDPE pipes and hose floats support hoses and pipelines used to transport water, slurry, and other materials in the mining and construction industries. These floats ensure that the hoses and pipes remain buoyant, preventing them from becoming damaged or obstructed. This support is crucial for maintaining operational efficiency and minimizing downtime in mining and construction projects. Hose floats are especially beneficial in mining operations involving abrasive materials such as slurry. Their durability and buoyancy help prevent wear and tear on hoses and pipes, extending their lifespan and reducing maintenance costs. In construction sites, these floats facilitate the transportation of water and other essential materials, ensuring that projects can proceed smoothly and efficiently.Agriculture

In agricultural applications, hose floats and HDPE pipe floats can be used in irrigation systems to keep hoses and pipes afloat in water bodies such as ponds, lakes, and rivers. These floats ensure that the irrigation pipes remain buoyant and adequately positioned, allowing for efficient water distribution to crops. This application is handy in large-scale agricultural operations where consistent and reliable irrigation is crucial for crop yield and quality.Aquaculture

In aquaculture, HDPE pipes and hose floats support the infrastructure for fish farming and other aquatic farming practices. These floats keep nets, cages, and feeding systems afloat, ensuring the equipment remains functional and accessible. The durability and buoyancy of these floats are essential for maintaining the health and safety of aquatic livestock.Disaster Response

Hose floats and HDPE pipe floats also play a vital role in disaster response efforts, particularly in flood management and emergency water supply. These floats can support hoses and pipes pumping floodwaters out of affected areas during floods. In emergency water supply situations, they ensure that hoses and pipes used to transport clean water remain buoyant and operational, providing essential support to disaster-stricken communities.